What Is Sweating Slab Syndrome and Why Should You Care? If your facility’s concrete floors are...

Warehouse Temperature Control - 5 Tips

Warehouse temperature control can be a major headache for any warehouse manager. It can also be difficult and strenuous on an HVAC unit. Let’s face it, a warehouse is a very big space. And in very big spaces, the temperature can be challenging to regulate. Nonetheless, doing so is vital because inventory can be ruined or spoiled due to “too hot” or “too cold” temperatures. Extreme temperatures are extremely rough on building equipment which can cause safety hazards and can affect employee productivity. All of this can greatly impact your bottom line.

So, how can you regulate the temperature within your warehouse effectively and efficiently? In this blog, we will offer some useful tips to help you with warehouse temperature control - without breaking the bank.

What Temperature is Ideal in a Warehouse?

The ideal temperature for warehouse space is not consistent across the board. It most definitely depends upon what type of inventory you hold. Ambient, cool, refrigerated, and frozen storage each require a different temperature set.

The Occupational Safety and Health Administration’s (OSHA’s) mission is to ensure that all employers provide safe and healthful working conditions for all employees. When it comes to the temperature in warehouses, OSHA does not formally regulate it. They do, however, recommend employers keep thermostats set between 68°-78° F.

5 Useful Tips For Warehouse Temperature Control

Tip 1: Add HVLS Fans

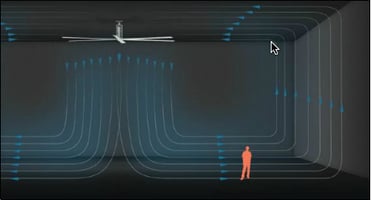

While HVLS fans won’t necessarily reduce indoor temperature drastically on their own, they can be very efficient at reducing effective temperatures when combined with commercial HVAC units. That’s because HVLS fans circulate the cool air from the AC throughout the entire space better than the AC unit can on its own.

HVLS fans also do an amazing job at destratifying the air. The fan’s rotation moves the air to the floor where it will create a jet of air across the building's floor to the walls. At the walls, the warmed air will rise again, to be blown to the floor once again. This cycle actually alters the molecular makeup of the air - blending, rearranging, cleaning, and more. This effective air movement helps to create an equalized temperature because it mixes the layers of air within the warehouse.

HVLS fans by MacroAir also have the ability to offer automated climate control systems utilizing thermostats. The thermostats act as temperature sensors to identify and dictate optimal operating speed and direction.

How Automated Fan Control Works

Automated fan control measures temperature and humidity levels at two points – the floor and the ceiling. This information is used to calculate the heat index, also known as the “feels like” temperature. Based on the heat index, the automated fan speed control software identifies the best operating speed and direction. Then it runs the fans accordingly.

With automated fan control, you simply select the desired temperature range and leave it to do its work. When the temperature rises above the desired temperature range, the fans automatically run in the forward direction to create a cooling effect. If the temperature drops below the desired temperature range, the automated fan control will run the fans in the reverse direction to redistribute the warm air overhead and eliminate hot and cold spots.

Tip 2: Seal It Up

Image by claudio losa from Pixabay

Properly sealing your windows and doors can also have a significant impact on controlling the temperature in your building. Without an effective seal to prevent drafts from entering your space, hot summer air and cold winter air will make their way in.

When hot air seeps in, it will counteract any cool air created by existing fans or air conditioning. Limit outside air from entering your building by sealing gaps in windows and doors and cracks in walls and ceilings. This also includes trailer gaps around docks. You can easily install curtain doors made of vinyl or plastic to line the loading dock bays. These tips are helpful for any time of the year.

Tip 3: Roof Material Check

Roofs can get dangerously hot! Roof temps can actually reach up to 150°F during hot summer months. A cool roof is a great way to maintain warehouse temperature control. Basically, a cool roof has a heat-repelling coating that can reflect the heat off the surface of the roof. Adding a cool roof can reduce the roof temp by up to 50°F.

Darker colored roofs actually absorb the heat and only reflect up to 20% of the sunlight which means the other 80% goes straight into your warehouse. Lighter-colored roofs reflect up to 80% of the sunlight, absorbing only 20% of that heat into your warehouse. Adding a cool roof will also extend the life of your roof and save you money on energy costs. Additionally, many states offer rebates for installing cool roofs.

In addition to cool roofs, consider effectively insulating your roof. There are a vast variety of insulations available for roofs. Some roof insulation materials include glass wool, polyester, cellulose, rock wool, and sheep’s wool. There are also a variety of forms, including blanket roll, batt, rigid board, spray foam, loose-fill, and structural insulated panels.

Tip 4: HVAC Maintenance

Photo by Sergei A from Pexels

An important tip to keeping your cooling costs down is to stay up to date on HVAC system maintenance. Replace filters as needed and make any repairs as soon as problems become known. Otherwise, your system won’t run as efficiently, you could end up with hefty costs, or you may even have to replace your system.

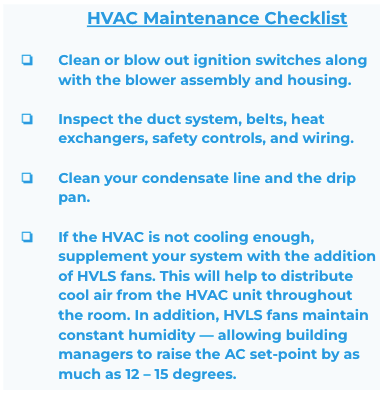

In addition to filter replacement, be sure to follow this HVAC maintenance checklist:

Tip 5: Smarten Up!

Another one of the best ways to control the temperature in your warehouse is by adding smart thermostats. Smart thermostats are a great tool for facility managers. They are energy-efficient and will save the building money in cooling costs. In addition, they are programable. The smart sensors will sense where your employees are within the warehouse. And when paired with smart sensors, smart thermostats will switch off the system automatically when no one is there.

Image by Gerd Altmann from Pixabay

Bottom Line

Warehouse temperature control can be an issue if not proactively managed. Nonetheless, doing so is vital. Product quality can suffer due to continuous temperature variations. Extreme temperatures are rough on building equipment which, in turn, can cause safety hazards and greatly affect employee productivity.

Trust MacroAir fans to aid in warehouse temperature control. MacroAir’s line of HVLS fans is tried and true. They are the original inventor of HVLS, and they continue to be innovative leaders in the industry.

Running in conjunction with your existing HVAC system, HVLS fans will help to improve warehouse temperature consistency. Along with the HVAC, utilizing the benefits of automated fan control will further help to regulate temperatures in your warehouse. Fans with temperature sensor control give the best of both worlds - energy savings and consistent comfort throughout the year.

Check out MacroAir’s direct-drive & gear-driven line of fans today.

Click the link below to help take back warehouse temperature control.

https://macroairfans.com/warehouse/