Proper installation of your HVLS ceiling fan is essential. It ensures your fan is running at peak...

6 Easy Tips to Improve Warehouse Air Circulation

Improving warehouse air circulation while reducing energy consumption and expense is one of the many challenges facility managers face today. The many processes continually running in these facilities mean that temperatures can run uncomfortably high. This isn’t healthy for people working within the facilities, and it leads to employee discomfort and lower productivity. One way of keeping extreme heat and energy spent in check is to diffuse it into the colder air outside. But how exactly do you achieve this?

Industry expert Jason Hornsby works with facilities managers in a variety of different industrial spaces to help achieve optimal airflow. Hornsby works with facilities managers in a variety of different industrial spaces to help achieve optimal airflow and reduce poor ventilation.

6 Easy Tips for Distributing Air in Your Facility More Efficiently

1. Lower the Effective Temperature

The first tip for improving warehouse air circulation in your facility is de-stratification. De-stratification is a key element in reducing the perceived temperature in a warehouse facility. The circulation of air reduces moisture in your body and makes you feel cooler. Several common ways people try to lower the effective temperature are

- High-speed fans

- Multiple pedestal fans

- Blowing cool air through air conditioning

- High volume, low-speed fans

Certain HVLS fans are proven to lower the “effective air temperature” by up to 7 percent. This cooling breeze effect is created when the large fan blades go in motion and fully distribute the heat layers while creating a large column of air. This makes high volume, low-speed fans significantly more efficient than small volume, high-speed fans.

2. Avoid Pedestal Fans

Although pedestal fans might be a quick and temporary solution to warehouse air circulation, their performance is poor, and they can present a safety hazard for employees. Some of the downsides to pedestal fans for industrial spaces are:

- Employee hazard from multiple extension wires

- Only creates a stream of cooling directly in front of the fan

- Increased energy costs

- Limited ability to lower the effective temperature

According to industry expert Jason Hornsby,

“I have worked with facilities that bring in up to 80 pedestal fans all over the factory floor. This meant 80 extension cords creating a serious tripping hazard and safety concern. In addition; the cooling of the employees was ineffective because as the employees move around while working, they are out of the airflow.”

As a solution to more efficiently increase the airflow in these facilities, Hornsby worked with this facility manager and was able to bring in two HVLS fans and take the place of all the pedestal fans.

This solution increases the airflow and cools the entire space by de-stratifying the heat layers throughout the entire building. This then will lower the effective temperature by 7 degrees.

3. Mount Your Fan on the Ceiling

Where you place the HVLS fans is one of the most important factors when distributing air. When positioned correctly, an HVLS fan can replace up to 10 conventional high-speed fans and could cost as low as 31cents a day to operate. A large ceiling-mounted HLVS fan will evenly distribute the airflow and ensure there are no heat pockets. This offers cooling for all facility areas while also cutting down on energy consumption by decreasing how hard your HVAC has to work.

4. Use the Right Size Fan Blade for Your Space

An important tip to help distribute the air in a facility is ensuring you have the right size blade on your fans. Many HVLS fans offer a variety of sizes for fan blades ranging from 8-24 ft. Selecting the right fan size is also critical to temperature distribution at the factory. The larger the fan, the slower the turn. This creates more volume, but a lower velocity of air. There are two key components that determine the appropriate size of a ceiling-mounted fan for your space

- Size of the room

- Height of the ceiling

Appropriately sizing your fan is important because of ceiling drop. If you have a 16-foot ceiling, the fan is going to drop to 13 feet automatically. On a smaller fan, this is fine. But on a larger fan, you need as much as a 5-foot drop. So you just brought the fan down to 11-feet.

Hornsby’s expertise tells us that

“When you don’t have a high ceiling but have a lower ceiling height, a short blade HVLS fan would work better. The reason is that small fans have a higher RPM (Revolutions per Minute) which increases velocity.”

The larger fan revolves much slower. It has a larger volume, but a lower speed. This is important to note because if you select too large of a blade size for your space, the fan might actually underperform compared to its counterpart.

5. Mount Your Fans Closer to the Ceiling

How close the fan is to the ceiling is also very important when the aim is to distribute air within the facility. If you mount it without a drop rod, that is called a “ceiling hugger.” The problem with that is that air can’t come from the top of your ceiling and into the blades of the fan. If you instead drop the fan, you allow the air to come in and go through the fan. The result is better air movement.

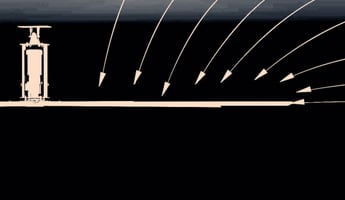

However, installing the HVLS fan higher also has advantages. For instance, if your HVLS fan is mounted at 20-feet, you would reach people as far as 70 feet away. But as you come closer to the ground, this diameter is reduced. A good demonstration is when you have a fan inside a cone. As you raise the fan, the cone spreads out; if you lower the fan the cone shrinks.

6. Measure for the Correct Spacing on Fans

The last tip for warehouse air circulation is to consider the spacing between individual fans. According to Hornsby, who has installed dozens of HVLS fans, placement is crucial. “If a fan covers 100 feet, then we would space our fans 100-feet apart. This way one fan would cover 50-feet in all directions.” So, the two HVLS fans, spaced 100-feet apart, would meet in the middle.

Summary

According to industry expert Jason Hornsby, if selected and installed properly, a high volume, low speed (HVLS) fan can be all you need to effectively distribute temperature within your facilities, increase employee comfort, and decrease your operating cost by up to 30%.

When looking to improve warehouse air circulation, it’s important to find a solution that addresses all the key components that contribute to both the perceived and actual temperature. When selected in the correct size and mounted at the right height, HVLS fans far outweigh other cooling techniques.

Jason Hornsby is the owner of Vector Sales and the Regional Sales Rep for MacroAir Fans. An expert with high volume, low-speed fans, Jason has spent more than 22 years focused on cooling solutions for industrial facilities that increase employee comfort and decrease energy consumption.