Facility managers and engineers are always looking for the most efficient and cost-effective ways...

Ventilation Benefits of High Volume, Low Speed Fans

Indoor air quality is important wherever you work, but can be a challenge to accomplish in large spaces. High Volume Low Speed Fans help existing HVAC systems blend fresh air into workspaces of all sizes.

Indoor air, when it isn’t continuously mixed with fresh air, becomes stuffy and smelly. Large spaces, high ceilings, and vast storage areas present ongoing ventilation and temperature battles.

Natural ventilation can help maintain good air quality, but this presents numerous other natural challenges – namely, it’s difficult to maintain a uniform air temperature. And while HVAC systems and box fans can help with distributing air and maintaining temperatures, they consume vast amounts of energy and are expensive to run. Plus, numerous box fans are needed to cool down large spaces, which can become a hazard.

To maintain indoor air quality and increase the comfort level and productivity of employees, high volume, low speed fans (HVLS fans) should be considered an efficient and cost-effective solution. Large-size commercial ceiling fans such as these solve most, if not all, air system inefficiencies.

Challenges of Natural Ventilation Systems

Natural ventilation is a great idea in theory. But these systems come with their own inherent challenges.

- Maintaining uniform temperatures is difficult

With a natural ventilation system, humidity and temperature levels must constantly be monitored. In the summer, it can be difficult to maintain temperatures and cool down the interior of a large warehouse if an outside breeze isn’t blowing. In areas with high humidity, opening doors and windows is simply not an option. In the winter, it may be too cold, yet keeping doors and windows closed causes heat build-up.

- The building must be oriented correctly

To take advantage of prevailing natural conditions, the building must be oriented correctly. However, this is not always possible, given individual outside terrain and logistics considerations. The area around the warehouse must be free of obstructions to allow for the free flow of air, while storage inside must be arranged to be conducive as well. Many times, these adjustments are simply not possible or feasible. - Build up of condensation

On high humidity days, water vapor is released into a building. Water vapor moves independently of air and always flows to the coldest point, such as concrete floors, which cool down at night. Once the concrete slab reaches the dew point as temperatures increase, condensation is formed on the floor, which poses real safety hazards to people and machinery. Condensation on roof beams can also drop to the floor and other surfaces, causing discomfort for people, and damage to machinery and materials.

Benefits of Using High Volume Low Speed Fans (HVLS Fans)

HVLS fans work in tandem with natural ventilation or HVAC systems and impart a number of benefits to business owners and facility managers including lower energy costs. In addition to supplementing natural ventilation or HVAC systems, HVLS fans also reduce or eliminate inherent temperature and ventilation challenges.

- Improved ventilation and indoor air quality

Although a building, including a warehouse, may have an air exhaust system in place, these systems often fail to thoroughly mix all of the inside air. This type of system gets short-circuited as doors or windows are opened and closed. Air pressure created in the suction of the exhaust looks to the path of least resistance and circumvents the intake devices. HVLS fans eliminate this problem as they continuously mix incoming fresh air, vastly improving indoor air quality. - Eliminate condensation buildup

Because HVLS fans constantly mix air from roof to floor, a constant state of thermal equilibrium exists inside the building. This does not allow condensation to form on the roof beams or floor, eliminating condensation dripping on product or machinery, as well as helping to ensure the floor stays dry and safe. - Provide heat destratification

In the winter months, heat stratification can cost an additional 25 percent or more since more heat is required to maintain floor level temperatures. Why so much? The rate of heat loss or transmission through the roof accounts for roughly 70 percent of the transmission losses inherent in all structures. The objective, then, is to even out the temperature gradient from floor to ceiling in order to reduce heat loss. One unique feature of HVLS fans is that they can run in reverse, which pushes the warm air at the top of the structure down to the floor effectively and efficiently evening out the temperature throughout the warehouse. The result is that one HVLS fan applied to 20,000 square feet of indoor space can easily return 20 percent of heating energy dollars. - Savings

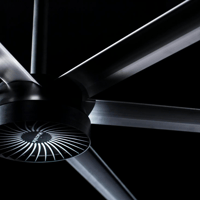

Quite simply, our patented 6ixBlade™ technology has been proven to lower heating and cooling costs by as much as 20 percent in a variety of building settings.

How to Choose the Right MacroAir Fan

HVLS fans are incredibly energy efficient — one HVLS MacroAir fan can replace up to 50 high-speed box fans while covering up to 20,000 square feet of facility space.

Which size fan should you choose? This depends on the size of your facility and its height. To maintain continuous air exchange, add one MacroAir fan per 20,000 square feet of space. The bigger the fan, the more air it can move over a larger space.

Check out MacroAir's entire selection of efficient HVLS fans by visiting the link below.

macroairfans.com

This article was modified from MacroAir’s January 2013 byline on barn and warehouse ventilation published by the Farm and Livestock Directory and Contractors Equipment Directory.