Warehouses and logistics facilities generally encompass massive square footage. They are filled...

HVLS Ceiling Fans for Warehouse

Warehouses and logistics facilities generally encompass massive square footage. They are filled with machinery, people, and even light fixtures that all give off heat. These spaces can suffer from climate zones, poor air quality, and uncomfortable temperatures. This can cause both energy inefficiencies and safety concerns for managers to mitigate.

High Volume, Low Speed (HVLS) fans offer a broad range of advantages for logistic and warehouse facilities. We interviewed subject matter expert Jonathan Jover about those advantages. He identified what he considers 5 key advantages to HVLS ceiling fans as a solution for warehouse cooling:

- HVLS fans are the most efficient air management systems on the market

- There is no rival to an HVLS fan in terms of air management

- HVLS fan energy consumption is very low

- The investment in an HVLS fan is very low compared to other comparable industrial fans

- The lifespan of an HVLS fan is very long

If you are a Warehouse Manager curious about HVLS fans as a solution for your building, there are important features you should examine. Based on our interview with Jover, we have identified six things you should know about how HVLS fans function in a large facility.

1. Big Energy Savings

.png?width=471&name=Energy%20Savings%20(1).png)

Finding a cooling solution that is both effective and cost-saving is a major concern for most Warehouse Managers. The ability of HVLS ceiling fans to decrease temperatures and run for pennies a day proves an ideal solution for many Facility and Warehouse Managers throughout the world. Running a ceiling fan will effectively create a cooling effect for your employees leaving them feeling 15° F cooler. In addition, your energy savings will blow you away. You will save up to 30% in your energy costs. Jover touches on this point from his global perspective of the issue in saying,

"I know that HVLS fans are contributing to the energy efficiency of big buildings around the world without sacrificing the comfort of people inside. If installing an HVLS fan means you now only need four air-conditioning units where you once needed five, you are more than paying for the purchase of your HVLS fan."

2. Year Round Usage

-2.jpg?width=478&name=Subaru_Sioux_Falls_Garage_AVD3_4%20(1)-2.jpg)

Did you know that HVLS ceiling fans are just as effective in the winter months? Schulte Subaru in Sioux Falls, SD is a 50,000 sq. ft. dealership that sells and maintains quality Subaru vehicles. With extreme South Dakota weather, Schulte Subaru wanted to install HVLS ceiling fans that kept cool air in the building during the summer months and also kept warm air in the building during the winter months. MacroAir's AVD370 and AVD3 HVLS ceiling fans effectively provide quality airflow for the entire space through ALL seasons.

Innovatively designed, MacroAir HVLS ceiling fans significantly cooled the dealership down during the hot summer months. Additionally, through the reverse function, MacroAir fans helped distribute heat evenly throughout the space during the extremely cold winters.

“I would tell anyone else starting a new dealership that they should definitely consider these fans. The airflow is amazing”. – Travis Johnson, Service Director, Schulte Subaru

3. Balance Temperatures

Logistics facilities require speed and pacing. This type of activity and traffic builds heat in a variety of climates. This build-up of heat is especially prevalent in warm summer months when logistic facilities have bays and loading docks open. Open bays and docks easily transfer the heat into the facility. Through the use of HVLS fans, warehouse facilities can destratify the air and blend the heat layers built up from the ceiling down. This mixing of air through a floor jet circulation provides significant cooling and removes trapped heat pockets that are created in large spaces.

One example comes from ST Fastening in Tyler, TX. They are the industry leading manufacturers and distributors of threaded self-drilling fasteners, foam closure strips, and other accessories. In their production process, employees are surrounded by very hot ovens that actually bake the powdercoat finish onto the hardware. Without HVLS fans, that heat sits at floor level causing employees to feel miserable. Installing MacroAir HVLS ceiling fans was essential in circulating the hot air. They run the fans in reverse all all times to suck the hot air up and blow it out and around, cooling it and destratifying those layers in the process.

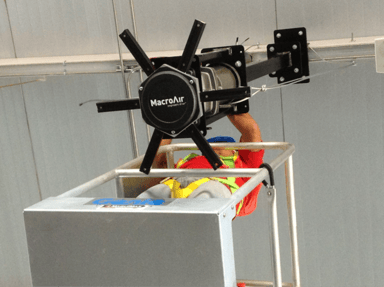

4. No Retrofit Required

HVLS fans require no ductwork. This provides versatility to use the fans as a standalone solution or in conjunction with an existing HVAC system. HVLS fans can move tons of cubic feet of air like a column. They do this with less noise, less turbulence, and less annoyance than a cumbersome HVAC system. As they move the air, they actually change its molecular composition; blending, mixing, and reconfiguring it.

Each MacroAir fan offers versatility in installation depending on the facility. Sizes range from 6-24 feet in diameter. Contacting the fan company direct is a great way to make sure you get exactly what you need in your facility. They will help you figure out how many HVLS fans you need and where to install your fans for maximum effectiveness.

5. Evaporative Options

In many climates, Facility Managers have relied on exhaust and open windows to stabilize the air. However, humidity takes many shapes. HVAC can try to substitute the air or drain the humidity. Industrial fans work at reducing the perception of temperature by increasing evaporation. The success of HVLS and its evaporative cooling is noted by Jover as he discusses one of his logistic facility installation successes. He states,

"One of our logistic facility clients found our HVLS fans installation over three cents per cubic feet more effective than their HVAC systems running alone."

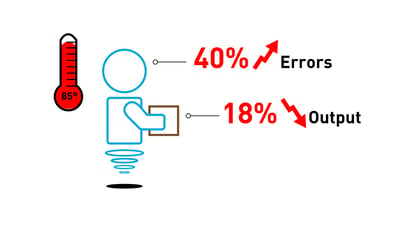

6. Keep Employees Safe and Comfortable

Warehouses can suffer from poor ventilation and airflow, which can be unsafe. When you add HVLS fans to a facility, it instantly increases air circulation throughout the large space, removing the stagnant, unsafe air and replacing it with fresh air. In addition, many manufacturing facilities can suffer from Sweating Slab Syndrome, which can be an extreme safety hazard. Installing HVLS ceiling fans will eliminate moisture on the concrete floor, leaving a safer work environment for your employees.

Big ceiling fans actually create a cooling effect for your employees leaving them feeling up to 15° F cooler as they work. When employees are more comfortable, fewer accidents happen in the workplace. Higher comfort levels also increase worker productivity.

Types of HVLS Warehouse Fans

HVLS Warehouse fans are available in a variety of sizes ranging from 6-24 feet in diameter. There are direct drive fans and gear driven fans.

MacroAir’s premium direct drive fans include the AVDX, AVD5, AVD3, and AVD370. Direct drive fans use a gearless motor. Because of this, they are lighter weight, quieter, and extremely energy efficient. Gear driven fans operate with a gearbox motor. MacroAir’s gear-driven line includes the AirVolution, AirLegacy, and AirLite. Gear driven fans are very reliable and are perfect for harsh conditions. In addition, all MacroAir fans are extremely easy to operate and come with industry-leading mechanical and electrical warranties.

Want to Know More About HVLS Fans?

The cooling needs of a warehouse facility can vary greatly depending on business operations. To save money on energy, keep occupants happy, and maintain processes and equipment, consider the use of HVLS fans and their return on investment. MacroAir offers an impressive, industry-leading selection of HVLS fans including both direct-drive and gear-driven. You can find more information on our line of premium fans by clicking the link below.

Learn More About MacroAir Fans

You can also reach out to one of our experts to find out more about how HVLS fans can benefit your space. Our knowledgeable representatives are here to answer any questions you may have at any time.