The quality of air in a warehouse is a key determinant of the level of productivity and efficiency...

How to Get the Best Return on Your Warehouse Cooling Investment

Constant movement and running machinery with lots of people are common scenes in warehouses. With such intense activity, heat from bodies and machinery is inevitable. A cooling system that creates a comfortable environment is important in order to ensure that such extreme temperatures do not hinder employee productivity or safety.

A genuine concern when investing in a cooling system is the return on investment. Conventional air conditioning systems come with extensive ductwork for circulation. In an ordinary warehouse, the ductwork will cover the storage areas, operational areas, offices, and meeting rooms. These duct systems come at a high cost – the bigger the warehouse, the higher the installation costs.

HVLS Fans

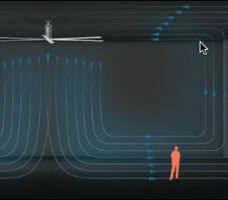

With high volume low speed (HVLS) fans, you can get a better return on investment (ROI) for the same or even better temperature regulation than a traditional HVAC system. HVLS fans move a large volume of air in each rotational motion due to their wide blade span and the slow speeds at which they operate. The result is better mixing of air over large spaces creating a comfortable environment in the warehouse. The effect of this on a business is lowered installation and operational costs. Where extensive duct work was needed in the past, a few MacroAir fans combined with the existing air conditioning unit will do the job. The HVLS fans needed to do the same job come at a fraction of the cost of installing air conditioning ductwork in a building.

Better Power Efficiency

HVLS fans use an efficient horsepower motor and consume up to 50 percent less power than a conventional ceiling fan. Combining an air conditioning unit with HVLS fans can further reduce energy costs. The fan mixes the cold and warm air from the air conditioning with the surrounding air and distributes it over much larger spaces.

During the cold season, warm air rises and collects near the ceiling of the warehouse. MacroAir HVLS fans can be run in reverse to draw up the cold air that is near the warehouse floor, mix it with the warm air, and spread it across the building. This type of heating is cheaper than running heaters in the air conditioning to warm the building in the winter. In case of extreme cold, the heater need only be run intermittently because the fan is constantly working to mix air to perfect temperatures.

Repair, Replacement, and Maintenance

One of the most common maintenance complaints is the air conditioning unit breaking down. The cost of repairing or replacing a unit is high. In a situation where the air conditioning unit breaks down during extreme temperatures, you may have to close your facility.

HVLS fans have very few incidents of breakdown, reducing your recurrent maintenance costs. They also have very long service lives guaranteeing that you won’t worry about replacement costs in the foreseeable future.

Overall, MacroAir HVLS fans result in better ROI when installed in any commercial space. These fans are also a greener alternative, creating a comfortable environment while reducing the environmental impact of temperature regulation.