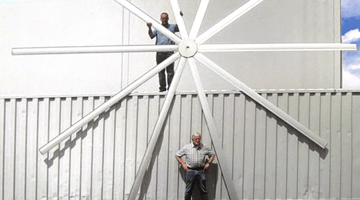

The pioneering spirit of MacroAir's founder, Walter Boyd, and his son, Eddie Boyd, is evident in...

3 Things to Avoid for the Best Fan Blade Design

High volume, low speed (HVLS) fans are extremely popular in warehouses and other industrial facilities because of their ability to move large amounts of air, creating a quiet, gentle breeze. However, some manufacturers make design choices that can reduce efficiency and increase operational costs. Here are the top three blade design mistakes to avoid for optimal fan performance and efficiency.

1. Adding Winglets to Fan Blades

One of the most common features introduced in HVLS fan design is the addition of "winglets" or curved end caps. While winglets are beneficial for reducing drag on airplane wings, they do not improve the performance of HVLS fans. Studies have shown that winglets actually increase torque, forcing the motor to work harder and reduce efficiency. Instead of helping airflow, winglets disrupt the continuous column of air that an HVLS fan is designed to produce. Additionally, winglets can add unnecessary weight to the fan, further straining the motor and reducing overall efficiency.

MacroAir fans are intentionally designed without winglets to ensure optimal performance and energy efficiency. By eliminating unnecessary torque on the blades, our fans maintain a smooth, continuous airflow with reduced strain on the motor. This not only enhances durability but also minimizes energy consumption, resulting in lower operational costs for businesses. You can see the positive results of the MacroAir fans without winglets in the AMCA Ceiling Fan Energy Index (CFEI) ratings that have recently been released. This should matter to you because a more energy efficient fan can equate to a better bottomline.

2. Inefficient Blade Shape in Fan Design

The shape of an HVLS fan blade significantly impacts its efficiency and airflow performance. Some manufacturers experiment with unconventional blade shapes, such as extreme curves or aggressive angles, in an attempt to optimize air movement. However, these modifications can create turbulence, disrupt smooth airflow, and force the motor to work harder, which again reduces efficiency.

MacroAir fans are engineered with precision-designed airfoil blades, inspired by NASA’s aerodynamic technology. Much like an airplane wing, the airfoil shape ensures optimal airflow by generating lift, creating a smooth, continuous column of air that enhances circulation. The longer, slender, and straight blade design reduces drag and improves efficiency while maintaining durability. The streamlined airfoil blade design also minimizes turbulence, reduces strain on the motor, and maximizes both comfort and cost savings in large spaces.

Imagine driving a sports car with a sleek, aerodynamic design versus a boxy, outdated model with lots of bells and whistles that just get in the way. The streamlined car cuts through the air with minimal resistance, improving speed and fuel efficiency, while the boxy car struggles against drag, wasting energy. MacroAir’s airfoil blades function the same way—engineered for smooth airflow with less resistance, maximizing efficiency and performance. Just as a well-designed car saves fuel and delivers a better ride, our fans optimize airflow while reducing energy consumption and wear on the motor.

3. Using Milled Aluminum Instead of Anodized Aluminum Blades

The material used for HVLS fan blades plays a crucial role in durability and performance. Several manufacturers use milled aluminum, which is more prone to corrosion, wear, and structural weakening over time. MacroAir fans, on the other hand, utilize anodized aluminum blades, a material commonly used in industrial applications where durability is crucial. According to the Aluminum Anodizers Council, when you anodize a blade it goes through an electrochemical process that strengthens the natural oxidation of aluminum, creating an ultra-durable, corrosion-resistant surface that is fully integrated with the underlying aluminum. This process makes anodized aluminum extremely resistant to damage from handling, installation, surface cleaning, and continuous use. Unlike coated materials, anodized aluminum will not chip or peel over time.

Did you know…Anodized aluminum is trusted across industries for its exceptional durability. It protects satellites in space, strengthens automotive trim and protective covers, and enhances building construction. Even high-end cookware relies on it for its strength and wear resistance.

MacroAir HVLS fans stand out because our fans incorporate anodized aluminum blades as a standard in every HVLS fan. By doing so, they ensure superior longevity, reduced maintenance, and optimal performance in their fans. Unlike most competitors that rely on milled aluminum, MacroAir fans provide a stronger, more resilient, and environmentally safe solution. In addition, anodized blades are color-stable and customizable, easy to maintain, and contribute to sustainable practices with minimal environmental impact.

Choosing anodized aluminum blades means businesses benefit from long-term reliability, durability, enhanced aesthetics, and significant reductions in maintenance costs.

Final Thoughts on Best Fan Blade Design

Selecting the best HVLS fan goes beyond just choosing a brand - it’s about looking closely at the elements of the fan, including the blades, to ensure thoughtful, intentional, and intelligent choices. After reading this blog, you know that best practices for choosing the best fan blade design including

- Opting for a blade design without winglets or other obstructions on the blade that disrupt airflow.

- Choosing well engineered blade shape with airfoil shaped blades to optimize airflow.

- Looking for high-quality blade material like anodized aluminium to improve durability, reduce corrosion, and improve performance.

Doing so will help you maximize airflow performance while reducing maintenance and energy costs.

As the inventor of HVLS fans, MacroAir engineers our fan blade design with precision and purpose to deliver superior air movement and long-lasting reliability. No gimmicks - just a damn good fan. Don’t settle for inefficient blade designs - upgrade to an HLVS fan built for performance and built to last.

Discover the MacroAir difference today! Click below to explore our industry-leading HVLS fans and see how they can transform your space.